How to Adjust a Pressure Switch

Pressure Switch Q & A: Question: From Todd L. – Alaska

Hi Colleen, I would like to learn how to adjust a pressure switch. I really need to improve our well water pressure at home. I checked the air pressure in the pressure tank and it’s set to 18 psi, does that mean the pressure switch is set to 20/40?

How do I know how many turns are needed to adjust a pressure switch? I would like to increase water pressure setting to 30/50 or 40/60 PSI, this is so confusing, I hope you can help! Thanks for your response, I always appreciate your professional advice.

Our water pressure is very low, my wife is complaining about our water pressure often, once again I find myself turning to your blog for the right answer! I’ve called around locally and no one seems that helpful, I’m just baffled.

I have read your other website many times over the years. I appreciate your commitment and endless articles, you’ve responded to my emails before and once again I look forward to to your response!

For a full updated tutorial about pressure switch on a well pump system

Pressure Switch Adjustment for Well Pump Instructions

Hi Todd, glad to see you back! I do remember you… let’s see if I can help you adjust a pressure switch for your water system.

WARNING: Be careful Todd, before you proceed with pressure switch adjustment you must power-down your water system, which means cut (turn-off) the electricity to your well pump completely!

Common sense would suggest there should be a quick-disconnect near the pressure tank, but common sense will not always prevail when it comes to home water systems. If there’s not a disconnect at the pressure-tank you’ll need to power-down at the electrical panel, if you’re not completely clear on this Todd you must not attempt to adjust the pressure switch, please call a professional!

I know you live a long way from town it’s better to be completely safe rather than have you take a long ride to the local morgue.

Pressure Switch Safety First!

There are live electrical contacts exposed on a pressure switch, one you remove the cap. If you touch them, especially being near water piping, there may be a serious of electrocution. Watch what you touch, or have a professional plumber / electrician adjust the pressure switch for you.

Even after you’ve turned off the power Todd, test to be sure it’s off, never assume that you are powered down! I rather go the electrical panel anyway the find the correct breaker to the pump, from experience I always lean on the side of caution.

There’s also a possibility that the electrical breaker is not correctly labeled.

I see lots of guys adjust without disconnecting the electricity, I was taught to do that by one of the engineers I trained under and I was electrocuted. It’s a really BAD idea to shortcut this step.

Unless you know exactly what you’re doing when you adjust a pressure switch you really should not be messing with a pressure system, those of us who do this work are trained and familiar with checking on other issues that may go unnoticed. We highly recommend that you have your water well system inspected and serviced every year by a professional,

However, I will answer your question Todd, I know you are in an area that’s difficult to get your system serviced. Let’s go through the complete steps and you will learn how to carefully adjust a pressure switch.

Well Pump Pressure Switch & Pressure Tank Air

I would find 20-40 PSI to be an intolerable water pressure, no wonder your wife is complaining! Unless the pump’s ability is questionable your submersible pump should easily build lots of pressure.

Let’s assume that it’s a submersible well pump, if I remember correctly you’re running a deep well submersible pump system. For the most part 30-50 is the lowest pressure generally acceptable but 40-60 PSI is much better.

If by chance you’re running a jet pump system then I would stay on a 30/50 switch because your jet pump may not have enough capacity to build 60 psi, if the contacts don’t open the pump will just keep running while try to build pressure. Best to not take a chance with a jet pump system, to many variables.

First, connect a hose to the hose-bib (tap) at the bottom of the pressure tank and completely drain off the tank. Don’t go dropping the hose into a floor drain unless you’ve tested the drain and know it’s open, half the time they’re not tested and can be plugged with concrete. Close the valve but leave the hose connected as you’ll need to test later.

By the way Todd, if the pump kicks in at this point the power is NOT off… the well pump should not start-up while you are draining the pressure tank off

It’s a good time to check that the pressure gauge is working is correctly or install a new gauge, the nipple can become restricted or plugged. If it’s restricted just get rid of it… they’re simple to install.

The air in the tank should be 2 lbs less than the kick-on pressure (when the pump engages), if you’re currently at 18 lbs then you will need to add air when the tank is completely drained of water, if you are set at 40/60 then you’ll require 38 lbs of air not 18 lbs.

Pressure Tank Air Adjustment

As you’re adding air keep checking the air pressure in the tank with a tire gauge. If it’s too high, bleed a little pressure off. If it’s too low, add air with a bicycle pump or air compressor. There is no rule suggesting you must adjust your pressure switch to 30/50 or 40/60 you could adjust to 35/55 – 45/65 but I would not tighten it down too much, as you will risk the contacts on the pressure switch not opening which disengages the pump.

It’s recommended that a 20 lb differential between the pump-on and pump-off is maintained. Far to often I will see a 30/50 pressure switch tightened down far to tight, not a good idea at all as the contacts may not open or close properly – it’s best to just purchase a 40/60 switch if you want more that 50 PSI.

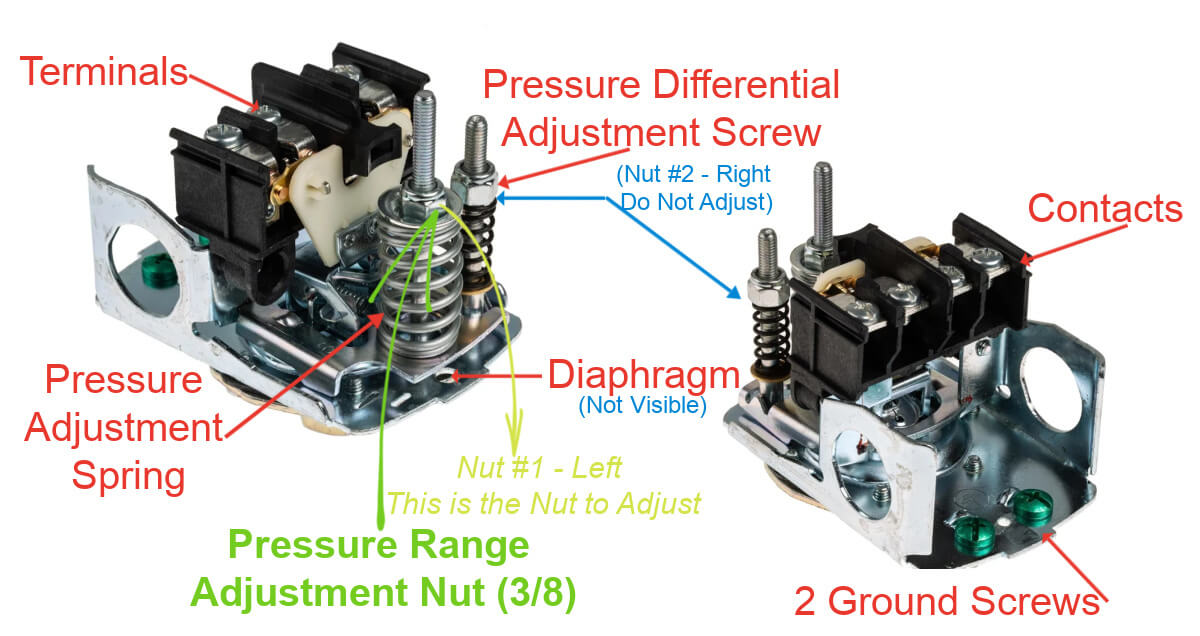

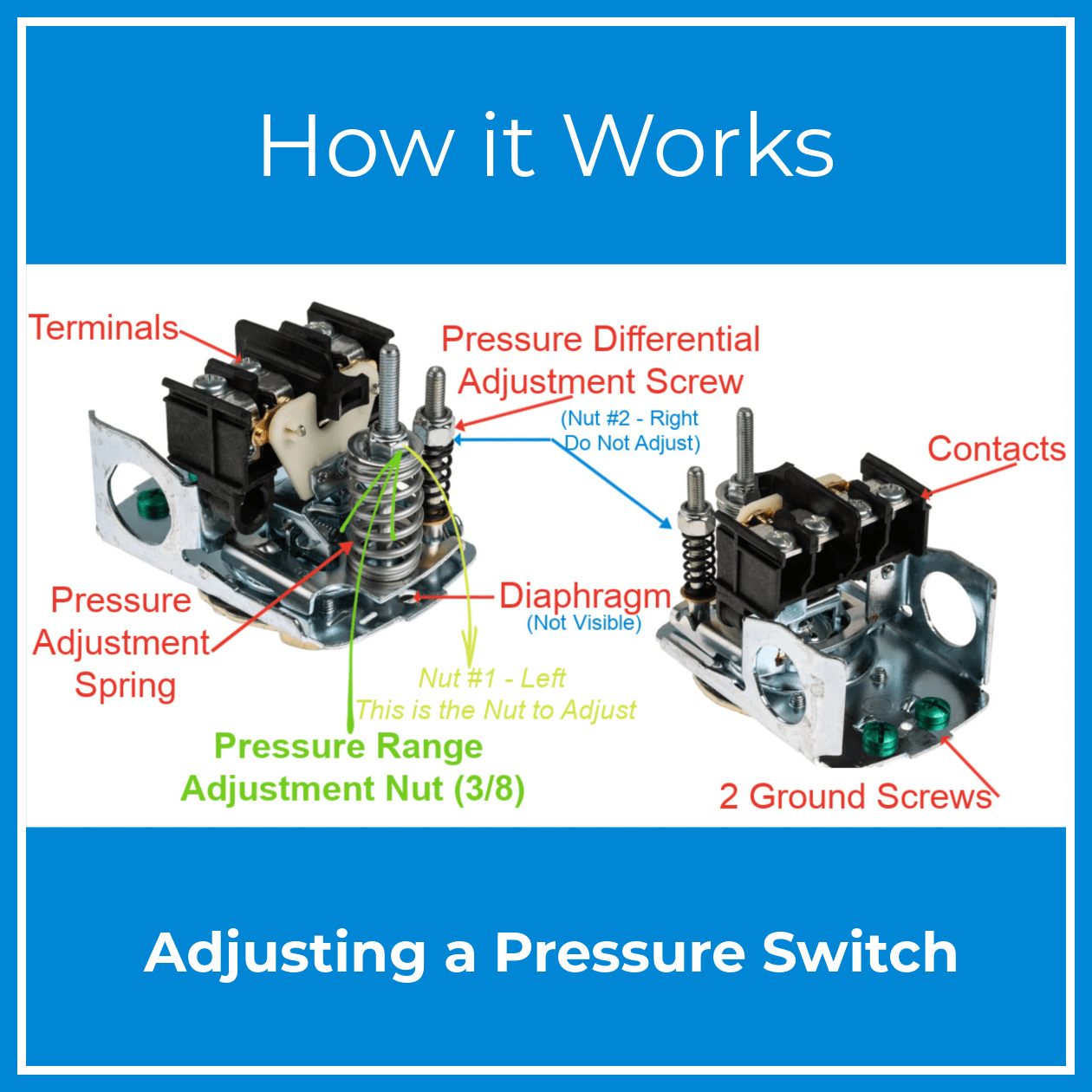

Cut-on/cut-off of a 40/60 PSI is the factory setting of a 40/60 pressure switch. A 20 PSI differential is standard and recommended. You can adjust the differential by turning the short adjusting nut on the pressure switch clockwise to increase or counter-clockwise to decrease the differential, it’s seldom required and pre-set at 20 lbs. I suggest not tampering with this setting (the short nut) unless there’s a reason to do so. You can throw things out of wack pretty quick.

Adjust the long thread nut (on left side) of the pressure switch, turning it to the right to increase pressure (each complete turn should increase the pressure about 1-1/2 lbs.) If your pump is cutting out at 50 PSI then it will need a few turns to increase to 60 PSI with a 3/8th open end wrench.

Slowly adjust, you may need to test it a few times. Don’t just go nailing it with a dozens turns… it will be to much. Maybe have someone at the electrical panel so they turn the power of and on for you. Speak to them via cell phone so they can clearly hear your instructions.

We typically install 40/60 PSI pressure switches for domestic use unless we are working on a little shallow well system with a small jet pump, you can also purchase a pressure switch with a low-pressure-cut-out (little brass lever to the side) and that’s a whole other topic.

I really dislike low-pressure-cut-out switches, they’re really a cheap fix for nothing. I never install them. Install a proper well pump protection system if there’s an issue or a concern, my advice it to always “Do the job right.”

Hopefully this helps you out Todd, power up the pump and ask your wife to enjoy a shower, you should have a happy wife! If there are any problems shoot me an email, I’ll walk you through it on the phone.