FRASER VALLEY

Geotechnical Drilling Methods

Geotech Drilling Solutions Serving

Vancouver, Chilliwack, Hope, Abbotsford, Clearbrook, Mission, Surrey, Langley, Fort Langley, Burnaby, New Westminster,

Coquitlam, Port Coquitlam, Maple Ridge, Pitt Meadows, Ladner, Tsawwassen, Richmond

FRASER VALLEY

Geotechnical Drilling

ESTIMATES

Vancouver, Chilliwack, Abbotsford, Clearbrook, Mission, Surrey, Langley, Burnaby, Coquitlam, Port Coquitlam, Maple Ridge, Pitt Meadows, Ladner, Tsawwassen

Fraser Valley Geotechnical Drilling Methods

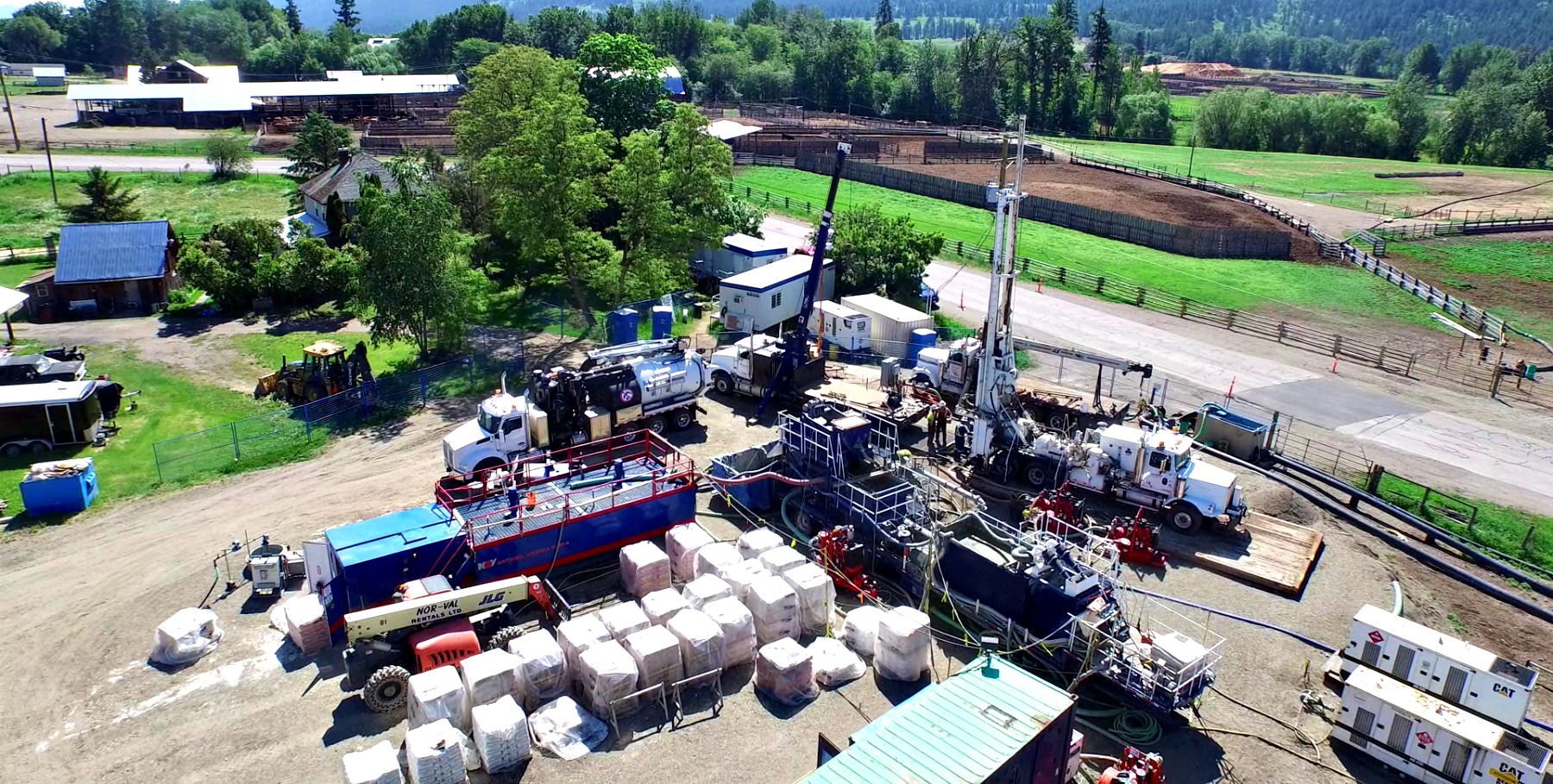

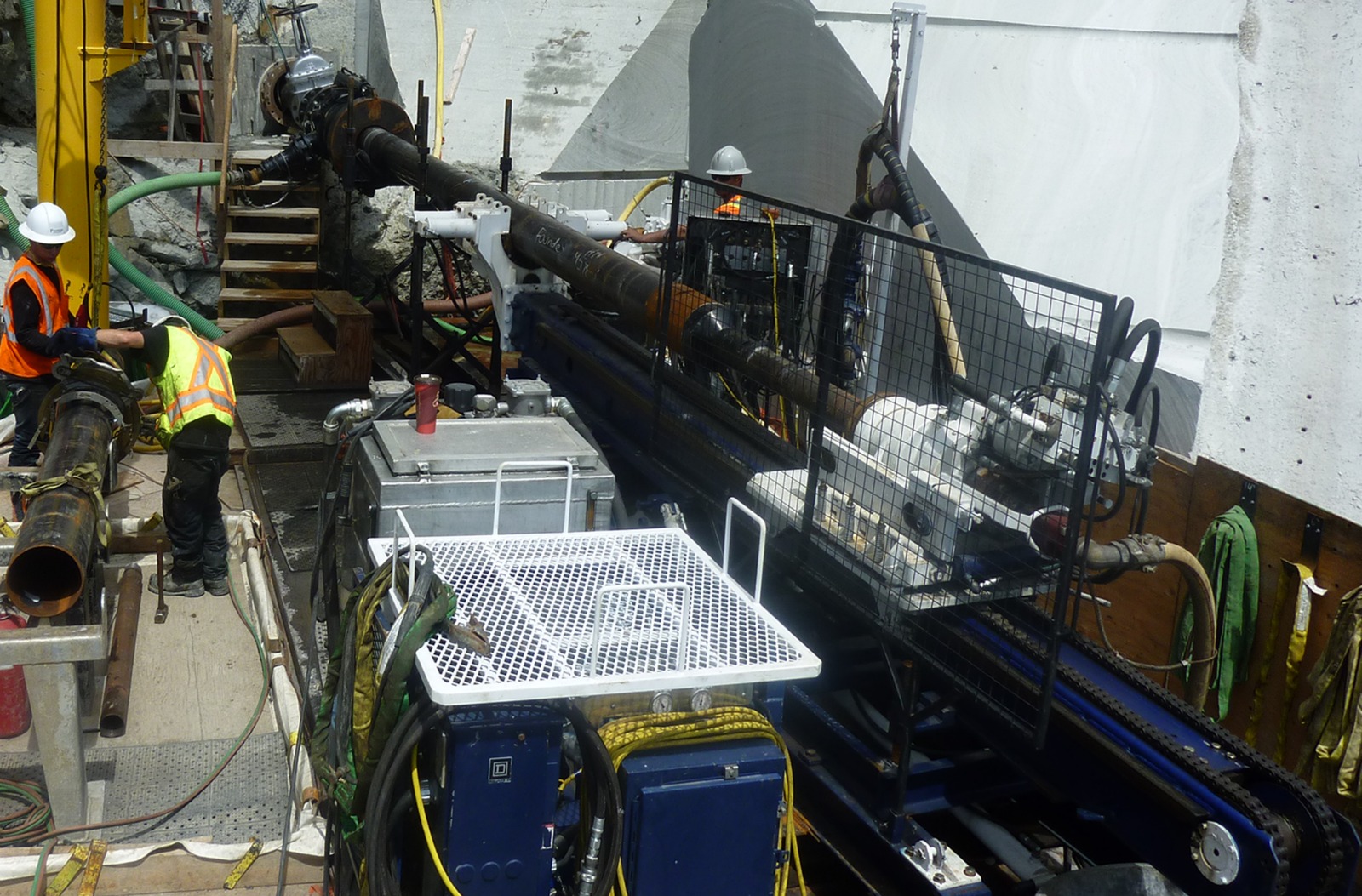

Fraser Valley Geotechnical Drilling specializes in geotechnical drilling, environmental drilling, geothermal drilling and exploration drilling. Fraser Valley Geotechnical Drilling is focused on constant improvement and growth that continues to make us an industry leader.

Any major geotechnical engineering project begins with a geophysical survey that will explain the type of soils that will be encountered. The earth is comprised of materials that have different physical properties such as bedrock depth, rock type, layer boundaries, water table, groundwater flow, locating fractures, weak zones, expansive clays, etc.

Geotechnical geophysical surveys are performed on the ground surface, within boreholes, and even from the water and air. Fraser Valley Geotech Drilling provides the best geotechnical drilling method to handle even the largest of geotechnical engineering project.

Regardless of your geotechnical drilling requirements Fraser Valley Geotechnical Drilling can handle a broad-spectrum of geotechnical problems our advantages of geotechnical geophysics are significant when it comes to site accessibility, portability, non-invasiveness, and operator safety.

Our Geotech drilling equipment is deployable underneath bridges and powerlines, in densely forested areas, at contaminated sites, in urban areas, on steep dipping slopes, in wetland terrains, on pavement or rock, and in other areas that are not easily accessible to many drill rigs or cone penetration test (CPT) rigs.co

Geotechnical Drilling, Exploration & Environmental

Fraser Valley Geotechnical Drilling offer a broad-scope of services, from geotechnical investigations and construction to marine investigations and hydrogeology.

We are focused on customer-oriented solutions and, therefore, depend on the project specific requirements and access availability, we have access to a wide variety of geotechnical drilling equipment to perform the job that the project requires.

With one of the most comprehensive inventories of drilling, sampling, coring and insitu testing equipment in the industry. Fraser Valley Geotechnical Drilling can provide the right equipment to perform a successful compact grouting operation as well as sonic drilling, dual rotary drilling, air and mud rotary drilling among others.

We have the ability to deploy a wide range of geotech drilling systems from man-portable drills, to large machines such as our Sonic or our Dual Rotary drills. The proposed drill rigs, systems and methodology for each project will be specifically developed thru the tendering process.

With available innovative geotech drilling systems, sampling and insitu equipment that cannot be purchased in the marketplace to undertake special assignments we encourage you to submit your project information online, we respond quickly.

We can modify existing equipment to meet a particular requirement. Our ability to manufacture or fine-tune our equipment, combined with our expertise sets us apart from other geotechnical drilling contractors. We keep to continually identify the latest drilling and geotechnical technology that we can implement as well as equipment to acquire.

Fraser Valley Geotechnical Drilling Service Area

Fraser Valley Geotechnical Drilling Service Area Includes:

Vancouver, Whistler, Burnaby, New Westminster, Chilliwack, Abbotsford, Clearbrook, Mission, Surrey, Langley, Coquitlam, Port Coquitlam, Maple Ridge, Pitt Meadows, Ladner, Tsawwassen, Whistler

Geotechnical Drilling Methods FAQ

Fraser Valley Geotech Drilling Services

Vancouver, Whistler, Burnaby, New Westminster, Chilliwack, Abbotsford, Clearbrook, Mission,

Surrey, Langley, Coquitlam, Port Coquitlam, Maple Ridge, Pitt Meadows, Ladner, Tsawwassen

A: Fraser Valley Geotechnical Drilling – Sonic Drilling:

Sonic drilling is a Geotech drilling method is based on the use of vibrations to create a cutting action at the bit face. From the sonic drill head, a series of high-frequency wave vibration are released through the drill reaching a resonant condition, which pushes the drill downwards into the earth, as the vibrations coincide with the natural resonant frequency of the drill pipe.

The resonant energy is produced in the sonic head by two counter-rotating weights. The operator shall control this energy to match the strata being encountered in order to achieve effective drilling.

The main components of a sonic drilling system are the sonic drill head and the drill rod. The sonic drill head is powered by hydraulic energy creating pressure waves, which allows to deliver forces from 50,000 pounds to 280,000 pounds with frequencies 50 to 150 Hz.

The sonic drilling technique allows to recover continuous samples of drilled material and samples other than the sonic core can be obtained via the casing having retrieved the core barrel. Therefore, sonic drilling can provide continuous, reliable and relatively undisturbed samples.

The Sonic Drilling Process Generally Consists of the Main Following Steps:

1. The core barrel is advanced as a result of the sonic vibration transmitted to the drill rod

2. The outer casing is advanced for the borehole to gain stability

3. The core barrel is retrieved from the outer casing

4. The sonic core is retrieved to the surface for verification of the soil conditions.

In general terms, sonic drilling can be used in depths up to 1,000 ft with casing diameters in the range of 4.5 – 5.5 inches and core sizes in the range of 4 to 10 inches.

Sonic drilling works well in almost all weak rock and soil and it can experience difficulty when used in strong rock or boulder conditions.

International Standard Practice ASTM D6914 Standard Practice for Sonic Drilling for Site Characterization & the Installation of Subsurface Monitoring Devices covers procedures for using sonic drilling methods in the conducting of subsurface exploration for site characterization and in the installation of subsurface monitoring devices.

One of the main advantages of sonic drilling relies on its fast execution. It is up to 3-5 times faster than other conventional drilling methods, such as rotary drilling or hollow stem auger. Because of this, it is the preferred method for jobs that require quick execution.

Additionally, the generated waste is much lower, hence reducing the cleanup costs. The sampling recovery rate is approaching 100%. No drilling fluid is required allowing for a significant reduction in cleaning up activities, although some water may be needed to the poured into the casing to keep the temperature of the sample under control and reducing the friction on the drill. Therefore, this technique is inherently clean producing only minimal waste making ideal for environmentally sensitive sites.

Other Advantages of the Sonic Drilling Method Are:

- Sonic drilling allows for a continuous core recovery

- Reduction in the risk of casing lockup allowing for easy casing retrieval during grouting operations.

- Minimal disturbance to soil sample

Safer method as fewer moving parts are required.However, this method may be slow and inefficient when strong rock is present, and it can be expensive to set-up the rigs and maintain the gear.

Sonic drilling is particularly effective for vulnerable civil structures such as dams, rail foundations, geothermal installations, environmentally contaminated sites, among others. Among its many applications, Sonic drills are being utilized extensively in the mining industry for mineral investigation, in the production of potable water wells, exploration for tunnels, underground excavations, general construction of micro-piles and earth retention, rehabilitation of critical structures and many others.

In special circumstances, sonic drills can be adapted to perform other drilling methods such as down hole air, hammer work, diamond bit rock coring or conventional wireline, among others.

This method relies heavily on the experience and skill of the operator. At Fraser Valley Geotechnical Drilling, our specialized, vast experienced and highly trained crew of operators can perform sonic drilling in a variety of situations and ground conditions.

Fraser Valley Geotechnical Drilling Performs Following Essential Equipment to Perform Sonic Drillings:

- RSD-150 Sonic Drill – the CSR-1000 Angel Drill developed by Drill Systems Inc has been customized to attach an RSD-150 resonant drill head

- RSD-100 Heliportable Sonic Drill – this system has been designed and manufactured by Fraser Valley Geotechnical Drilling to provide our clients with a high powered Heliportable Sonic Drill that could meet their project demands in remote locations

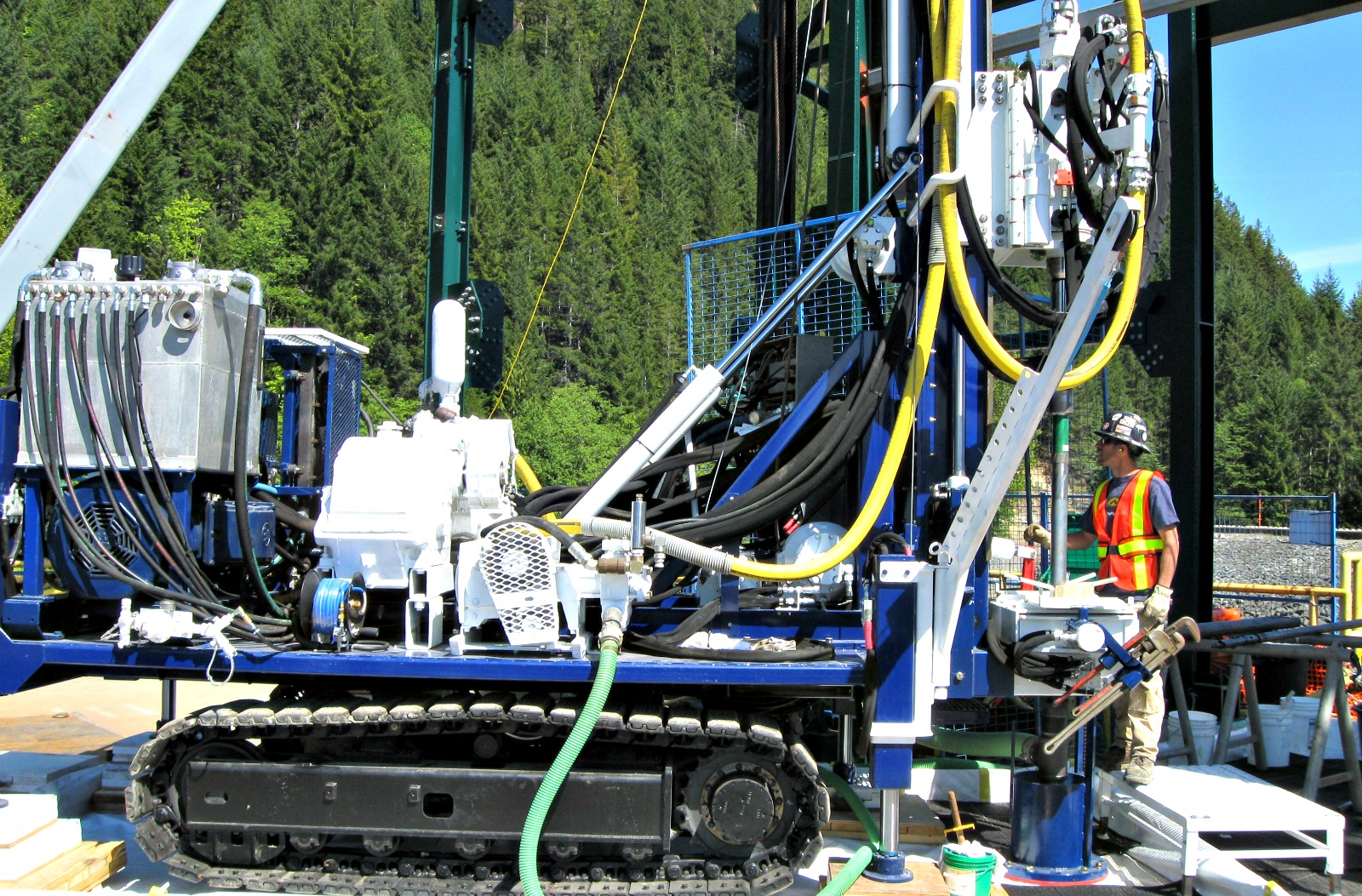

- LS600C Track Mounted Sonic Drill – this track mounted sonic drill features a pneumatic isolation system inside the head, preventing resonant energy from transmitting to the drill rig. This directs the maximum amount of energy down the drill string to the face of the bit for improved penetration rates. Its advanced design allows heads to last longer, drill faster and go deeper. A Continuous Sonic Core Sampling to 500 feet can be achieved.

In both the RSD-100 and RSD-150, the head does not utilize eccentric masses as conventional sonic heads do in today’s market. The revolutionary piston design in the head has fewer moving parts that do not subject eccentric loads to any bearings, thus making it more reliable than conventional sonic drills.

Drilling Estimates Fraser Valley Geotechnical Drilling or Tap-to-Call 778-949-4039

A: Fraser Valley Geotechnical Drilling – Dual Rotary Drilling:

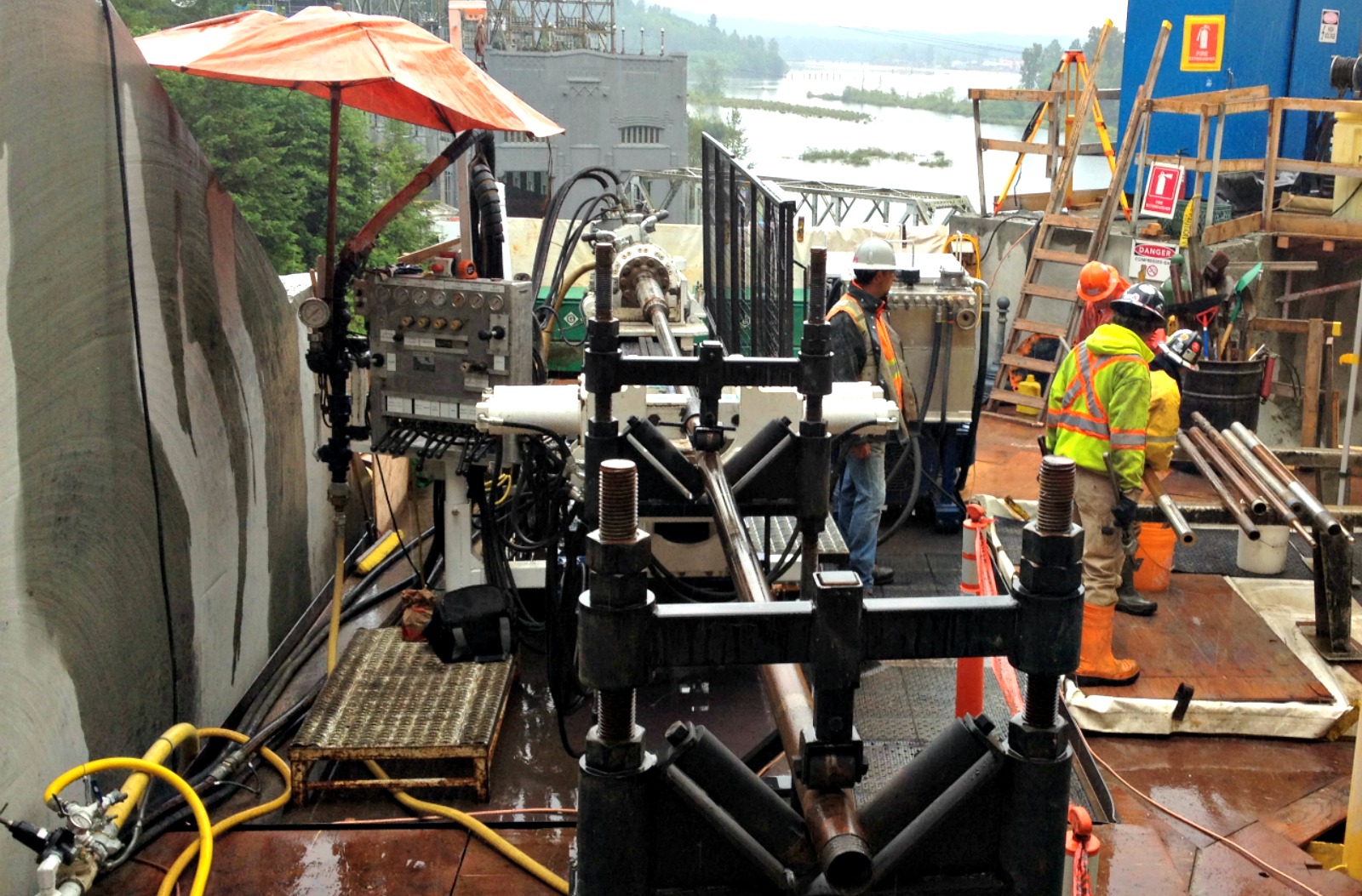

The dual rotary drilling is a type of drilling method using rotary technology, which is characterized focusing a sharp and rotating drill bit driven into the ground through the impacts of a hammer. Dual rotary uses an upper and a lower head drive to advance the drill bit and casing, while the rotary forces are transmitted to the casing through jaws. The lower drive is used to transmit rotational, pull-down and pullback forces to the casing.

The top drive works independently from the lower drive and it has its own hydraulic feed system. This allows the drill to be positioned ahead or behind the casing show. Therefore, the position of the bit changes relative to the bottom of the casing. Once the required casing depth is achieved, the top drive keeps drilling an open borehole like a conventional top drive. Cutting are usually retired with air by pumps can also be used for circulation drilling.

When encountering competent stratum, the drill casing may be advanced as the borehole is cut keeping therefore the borehole open during the drilling operation. Therefore, strong rock can be drilled in an open hole without requiring the use of casing.

Dual rotary drilling is particularly useful in unconsolidated overburden material such as sand, gravel, cobbles or boulders where other methods would struggle.

The Main Components of a Dual Rotary Drill are the Following:

- Hydraulic Feed System: used to raise and lower the top and lower drive

- Lower Drive: this drive is used as a breakout and spinner for drill pipe, hammers and thread casing.

- Top Drive: independent tilting hydraulic drive used to facilitate the loading of drill pipe and casing.

- Cuttings Discharge Swivel: used to divert all the cutting that rise up the space between the drill pipe and the casing.

- Casing Shoe: a carbide-studded shoe, which is welded onto the casing, is used to cut through hard stratum as the casing rotates.

- Casing Jaws: these jaws are used to connect the lower rotary drive with the drive.

The main advantage of this geotechnical drilling method relies on its cost effectiveness and great performance when drilling boreholes in strong or difficult stratum.

The dual rotary drilling method has proven itself to be a feasible alternative to more conventional methods when drilling in unstable overburden is required. This degree of flexibility and versatility is considered the main advantage of this method.

Dual Rotary Drilling Can Be Used in a Variety of Circumstances and Ground Conditions:

- Water well drilling, domestic wells with depths up to 1,000 to 2,500 ft.

- Well mud disposal, elimination of mud in wells.

- Construction Drilling, dual rotary allows to drill through debris or large boulders

- Dam rehabilitation, drilling of grout injection holes

- Tie-back holes

- Existing piling, dual rotary allows to re-drill existing piles

- Mine shafts

- Oilfields, dual rotary can be used to drill mouse holes and install conductor casings

- Environmentally sensitive drilling projects

Furthermore, the dual rotary rig can also be used as a conventional top-drive drill with the advantage of a tilting top drive.

Fraser Valley Geotechnical Drilling has the equipment and the experience to offer high quality dual rotary drilling. We have acquired a DR-24 dual rotary barber in 1997, which has been adapted and modified to our existing Barber drills to provide a wider variety of applications with a single drill.

We are able to provide a large variety of threaded casing from 7” to 16” diameters. This can be used for water wells, instrumentation and any project that does not require permanent casing. The threaded casing permits faster drilling rates for better production and less material costs for reduced project costs.

The Dual Rotary drill rig was designed to drill through extremely coarse overburden formations. The offered casing sizes are 6” to 24”. The top drive travel is 26 ft. and the lower drive travel is 12 ft.

DR-24 rigs have been successfully utilized to drill large diameter industrial & municipal wells to depths of 1,000 – 2,500 ft. (304 – 762m) by telescoping the casing method to accomplish the required casing depth.

Contact Fraser Valley Geotechnical Drilling or Tap-to-Call 778-949-4039

A: Fraser Valley Geotechnical Drilling – Air Rotary Drilling:

Air Rotary Drilling is also referred to as pneumatic percussion drilling, rotary drilling is a type of drilling in which a gas (usually compressed air or nitrogen) is used to maintain a cooled drill bit, bring the drill cuttings up and keep the borehole stable.

The borehole is done by rotating a drill bit mounted at the bottom of a drill pipe. The air is provided by a compressor, which moves the air to the swivel hose connected to the drill pipe, needing to maintain an up-hole velocity of approximately 3,000 feet per minute. The cuttings are removed from the area when the air going down the drill pipe leaves through small ports, pushing the cuttings to the surface.

Air rotary drilling is an effective method for borehole drilling in both unconsolidated and consolidated strata and it’s commonly used to perform deep drillings in rock formations. Because of the lack of fluids being introduced into the borehole, the samples are not at risk of being washed away or disturbed by the drilling fluid.

Air rotary drilling method is more effective than other drilling techniques as the air effectively cleans the bottom of the borehole allowing for a permanent contact between the drill bit and the rock. Air rotary drilling commonly uses a blade, Polycrystalline Diamond Composite or a tricone bit to penetrate the ground.

There are numerous applications for air rotary drilling, such as water well development, monitoring well construction, open hole drilling and hard rock drilling, among others.

The Main Advantages of Fraser Valley Geotechnical Drilling Air Rotary Drilling Methods:

- Penetration rates are relatively high

- Required casings are kept to a minimum

- Quick and easy rig mobilization

- Easy to install well screens as part of the casing installation

- High efficiency

- Relatively low cost

- Extended bit lifespan

- Low environmental impact

- Reduced cleaning process

However, air drilling is not recommended when fluids such as water and oil are foreseen to encountered as the air density is too low to be able to move these fluids to the surface and they will fall into the bottom of the borehole causing problems with the drilling.

Other disadvantages area the potential for fires and explosions due to the use of gases used in the process, the need for frequent replacement of the drilling bits when drilling in hard and abrasive sands and the risks of using this technique in contaminated formations, as the air can transport the contaminated material to the surface where the crew would be exposed.

Fraser Valley Geotechnical Drilling has the Equipment Available to Provide Top Quality Geotech Drilling Services

• HT Series Drills – Helicopter Transportable

HT Series Drills were specifically designed and manufactured in order to meet requirements for specialized drilling equipment for more remote drilling sites.

These compact, yet powerful air rotary drills are exceptionally versatile. They are of modular design, they can be broken down and installed on various platforms, be it skids, truck or tracked carriers. They are capable of drilling vertical, incline or horizontal holes.

• HT 500 Series Drill

The HT-500 series drill was specifically designed and manufactured to meet requirements for specialized projects and accessibility to remote drilling sites. The HT-500 is the smallest top drive drill and has been utilized in a wide variety of projects. It is very versatile and also can be equipped with an electric power pack for indoor operations.

The HT-500 Series Drill is very easily dismantled and transported by helicopter and requires minimal time to assemble and operate. The drill, although compact, has field proven itself many times and has always met or exceeded our expectations, with an extensive inventory of tooling and parts to support all operations of the HT-500 and to meet your project requirements.

HT 500 Series Drill Capability

- Mud Rotary Drilling, Air Rotary Drilling, Wireline Coring BQ to PQ

- Odex and Down Hole Hammer Drilling

- Geotechnical Investigations and Sampling

- Grouting, Anchors and Piling

- Water Well Drilling and Environmental Drilling

- Offshore Marine Drilling on Small Platforms

- Mineral Exploration,

- Heliportable (HT)

• HT 700 Series Drill

The HT 700 Series Drills were specifically designed and manufactured for use to meet requirements for many specialized drilling projects and accessibility to remote drilling sites. These compact, yet powerful drills are extremely versatile. The modular design of this this allows the HT 700 Series Drill to be quickly switched and mounted on skids, truck or tracked carriers. These specific drills are capable of drilling vertical, incline or horizontal holes

HT 7000 Series Drill Equipment Capability

- Mud Rotary Drilling, Air Rotary Drilling, Wire line Coring BQ to PQ or Auger Drilling

- Odex & Down Hole Hammer Drilling

- Directional Drilling

- Geotechnical Investigations and Sampling

- Grouting, Anchors and Piling

- Water Well Drilling and Environmental Drilling

- Heliportable (HT)

• HT 750 Track Rig

The HT 750 Track Rig Drill was specifically designed and manufactured to meet requirements for specialized drilling equipment for more remote drilling sites.

These compact, yet powerful drills are very versatile. They are of modular design, they can be broken down and installed on various platforms, be it skids, truck or tracked carriers. They are capable of drilling vertical, incline or horizontal holes.

- Mud Rotary Drilling, Air Rotary Drilling, Coring or Auger Methods

- Odex and Down Hole Hammer Drilling

- Directional Drilling

- Geotechnical Investigations

- Geothermal Drilling

- Grouting, Anchors & Piling

- Water Wells & Environmental Drilling

- Offshore Marine Drilling

- Mineral Exploration

- Heliportable (HT)

• HT 1000 Top Drive Rotary Drilling Rig

The HT 1000 Series Drills are all modular and heliportable to be transported to remote locations worldwide. The modular design of this drill also allows the rig to be easily switched and mounted on skids, truck or tracked methods of transportation..

The HT 1000 rig can be constructed to drill angle or horizontal holes. This drill is powerful enough to meet specific project demands for capacity in a relatively compact package. This drilling rig has shown to be very dependable and effective in all fields of application. With an extensive inventory of tooling and equipment choices to accompany the HT 1000 Top Drive Rotary Drill, Fraser Valley Geotechnical Drilling has the ability to accommodate all project requirements.

HT 1000 Series Drill Equipment Capacity

- Mud Rotary Drilling, Air Rotary Drilling, Wireline Coring BQ – PQ, Auger Drilling

- Odex and Down Hole Hammer Drilling

- Horizontal or Directional Drilling

- Geotechnical Investigations, Insitu Testing – Disturbed and Undisturbed Soil Samples, Overburden Coring

- Grouting, Anchors & Piling

- Drilled Water Wells and Environmental Well Drilling

• HT 2000 Top Drive Rotary Drilling Rig – Low Clearance Mast

The HT 2000 Series Drills were specifically designed & built for applications when drilling equipment is required for defined head-room access. These drill rigs were constructed with a lot of power in a compact package. HT indicates the drills can be adapted for helicopter transportation, the HT Series Drills are modular in design.

The HT 2000 Top Drive Rotary Drill Rigs are explosion-proof and can be operated in un-ventilated surroundings such as the inside of buildings, the rigs are built with XP electric motors. The drill rig’s modular design enables us to easily dismantle and re-assemble for various methods of transportation. Transportable via barge or a large helicopter if necessary. The HT 2000 Series Drills can also be assembled to drill inclined or horizontal holes.

This drill rig can also be loaded directly into a shipping container and shipped by ocean to international destinations.

HT 2000 Top Drive Rotary Drill – Low Clearance Equipment Capacity

- Mud Rotary Drilling, Air Rotary Drilling,

- Wireline Coring – BQ to PQ

- Conventional Large Diameter Holes up to 16”

- Odex & Down Hole Hammer Drilling

- Geotechnical Investigations

- Water Well Drilling & Environmental Drilling

- Grouting, Anchors & Piling

• HT 2500 Top Drive Rotary Drilling Rig

HT 2500 Top Drive Rotary Drill is typically utilized for Geotechnical Investigations, Insitu Testing, Disturbed and Undisturbed Soil Samples, Overburden Drilling including Geotechnical Construction Projects.

HT 2500 Top Drive Rotary Drill Equipment Capability

- Mud Rotary Drilling, Air Rotary Drilling

- Wireline Coring BQ to PQ, Auger Drilling

- Odex and Down Hole Hammer Drilling

- Horizontal and Directional Drilling

- Geotechnical Investigations, Insitu Testing Disturbed and Undisturbed soil Samples and Overburden Coring

- Grouting, Anchors and Piling

- Water Wells and Environmental Wells

- Production Coring

• CSR-1000 Top Drive Rotary Drilling Rig

The CSR-1000 has a top drive rotary head permitting mud rotary drilling, air rotary drilling and coring procedures to be performed on the same drill chassis as the Becker. The CSR-1000 has the power and capacity to drill large diameter holes to greater depths than most other top drives due to the pullback power & large main winch ability.

• RSD-100 Track Mounted Rotary Drilling Rig

The RSD-100 Track Mounted Rotary Drill is one of the larger track mounted top head drive rotary drill rigs Fraser Valley Geotechnical Drilling has available. The drill is equipped with all the necessary pumps and tooling to perform all types of rotary drilling and can be fit with an auxiliary air compressor to provide a full range of air drilling techniques as well. The drill can also be configured to drill angle and horizontal holes.

• Schramm T-685WS Rotadrill

The Schramm T-685WS Rotadrill can drill a 24” diameter hole that exceeds 1,100 feet in 50°c temperature with no production delays.

The drill is skid mounted and can be placed and set-up in a single shift. The rig is additionally equipped with a Drilling Parameter Recorder (DPR) to supply required data. The Schramm drill can be conveniently dismantled and moved in a Hercules aircraft for accessibilty to remote areas.

Schramm T-685WS Rotadrill Equipment Capability

- Mud Rotary

- Air Rotary

- Overburden Casing Systems, Down Hole Hammer

- Anchors and Piling

- Incline Holes

- Large Diameter Bulk Sampling

- Water Wells

Simco 5000 Top Drive Rotary Drilling Rig

The Simco 5000 is one of the larger truck mounted top drive drill rigs the Fraser Valley Geotechnical Drilling has available. This rig has the ability to be equipped to easily meet the needs of nearly any type of drilling plan requirements. The drill rig has been custom modified from factory and has received substantial upgrades to greatly advance it’s original factory performance with the capacity to meet the demands of very specialized projects.

This specific drill is fitted with all the required pumps and tooling to handle many types of rotary drilling, in addition the rig can be equipped with an auxiliary compressor to implement a full-range of air drilling techniques.

This drill has been used in hundreds of Marine offshore programs and is conveniently adjusted to marine vessels and has a heave compensated rotary head assembly to allow for optimal drilling performance in not so ideal sea conditions.

Simco 5000 Top Drive Rotary Drill Rig Equipment Capability

- Mud Rotary Drilling, Air Rotary Drilling,

- Coring BQ to PQ & CP Coring

- Odex, Symmetrix and Down Hole Hammer Drilling, Reverse Circulation Systems

- Geotechnical Investigations, Insitu Testing, Disturbed & Undisturbed Soil Samples, Overburden Coring

- Heave Compensated Offshore Marine Geotechnical Drilling System (Also Used with Wison Deep-water Offshore CPT/Sample System)

- Casing Installation from 2” to 10”

Simco 5000 Top Drive Drill Rig Capacity

- Maximum HQ Core Depths to 3,000 ft.

- 8” Mud Rotary Drilling to 1,000 feet

- 6” Odex / OVB Casing Systems to 300 feet

- Drill Hole Diameters—2” to 16”

* Capacities contingent on ground condition

Contact Fraser Valley Geotechnical Drilling or Tap-to-Call 778-949-403

A: Fraser Valley Geotechnical Drilling – Mud Rotary Drilling:

Mud rotary drilling is one of the most common soil and rock drilling types. This method is like air rotary drilling, but in this case, drilling mud is injected via the drill string in order to act as a lubricant to reduce the friction and cool down the drilling bit. The borehole is drilled by rotating a drill bit mounted at the bottom of a drill rod, which cuts the ground formations at the bottom of the borehole into cuttings, which are transported to the surface by the mud and deposited into a mud pit. The mud pit stores the remaining residue in the borehole caused by drilling, which is later reused.

During the drilling process, the weight and viscosity of the mud helps keeping particles from floating as drilling is taking place. These parameters shall always also be monitored during drilling operations.

Mud rotary drilling uses rock or a tricone bit attached to the bottom of the drill string. Mud is used to stabilize the borehole as the drilling process is taking place. During the drilling operation, a mud wall cake is created on the perimeter of the borehole, which maintains loose material stable, while also sealing off potential gas zones that present a hazard.

International Standard Practice ASTM D5783 Standard Guide for Use of Direct Rotary Drilling with Water-Based Drilling Fluid for Geoenvironmental Exploration and the Installation of Subsurface Water-Quality Monitoring Devices covers how direct (straight) rotary-drilling procedures with water-based drilling fluids may be used for geoenvironmental exploration and installation of subsurface water-quality monitoring devices.

This mud rotary drilling is ideal for unconsolidated ground, alluvial and loose geological formations. Mud rotary drilling is commonly used in the production, monitoring and de-watering of water wells (local, industrial, mining) as well as seismic testing, shale deposits and water quality testing, among others. The most common use of the technique is when drilling through soft rocks, sand and clay layers in the search for coal, oil or gas.

Furthermore, sampling is possible in mud rotary drilling via split-barrel and thin-wall samples can take place.

Direct-mud Rotary Drilling Provides Several Advantages:

- Relatively lower cost

- Increased safety avoiding potential gas zones

- Ability to keep the borehole stable

- Ability to drill through unconsolidated ground conditions

- Easy to switch out drill string to obtain samples

- Efficient drilling method enabling to achieve up to several thousand feet depths daily

However, direct-mud rotary drilling is not recommended when drilling in and around dams or in the presence of large, poorly stabilized boulders or karst (cavernous) conditions are unsuited for direct-mud rotary drilling. This method is not suitable for drilling in embankments due to the exerted fluid pressure.

Fraser Valley Geotechnical Drilling Understands that Specialized Projects Requires Essential Equipment to Perform Sonic Drillings:

- RSD-150 Sonic Drill – Fraser Valley Geotechnical Drilling has customized the CSR-1000 Angel Drill developed by Drill Systems Inc to attach an RSD-150 resonant drill head.

- RSD-100 Heliportable Sonic Drill – this system has been designed and manufactured by Fraser Valley Geotechnical Drilling to provide our clients with a high powered Heliportable Sonic Drill that could meet their project demands in remote locations.

- LS600C Track Mounted Sonic Drill – this track mounted sonic drill features a pneumatic isolation system inside the head, preventing resonant energy from transmitting to the drill rig. This directs the maximum amount of energy down the drill string to the face of the bit for improved penetration rates. Its advanced design allows heads to last longer, drill faster and go deeper. A Continuous Sonic Core Sampling to 500 feet can be achieved.

In both the RSD-100 and RSD-150, the head does not utilize eccentric masses as conventional sonic heads do in today’s market. The revolutionary piston design in the head has fewer moving parts that do not subject eccentric loads to any bearings, thus making it more reliable than conventional sonic drills.

Contact Fraser Valley Geotechnical Drilling or Tap-to-Call 778-949-4039

A: Fraser Valley Geotechnical Drilling – Becker Hammer Drilling:

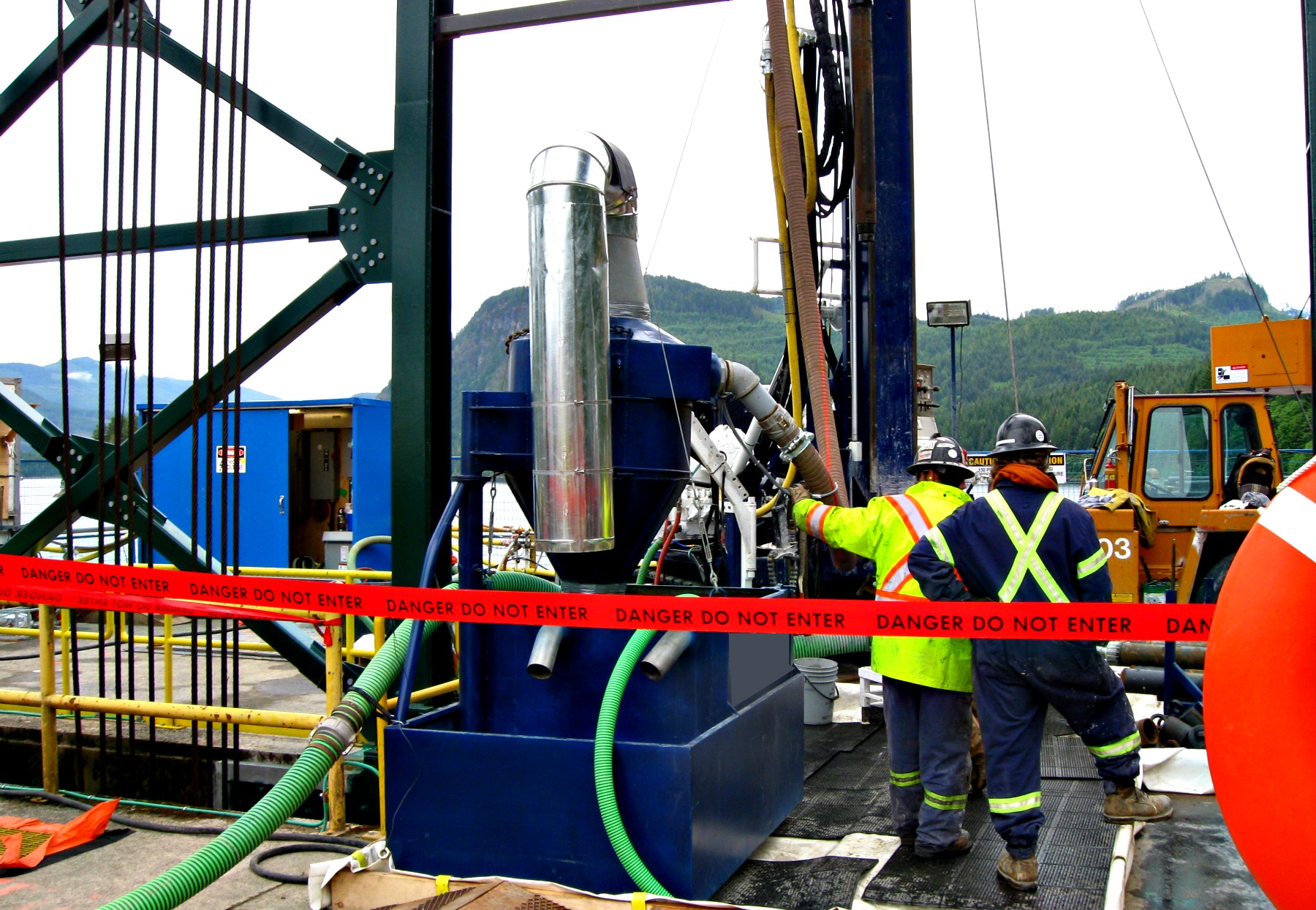

The Becker penetration test is a large-scale in-situ penetration test suitable mainly for gravelly soils. The Becker Hammer Drilling method was developed in Canada in the 1950’s for oil exploration and drilling operations at gravel sites. The Becker Hammer drilling method consists of driving a string of double wall casing into the ground using a compact double-acting diesel pile driving hammer.

The Becker Hammer drilling method consists on a double wall drive pipe which is driven by a percussion hammer while air is inserted down the annulus of the drive pipe. A AP-1000 diesel hammer is normally used. The compressed air is used to bring up to the surface the material drilled by the drive bit. This discharged material is stored in suitable containers as it is coming up and samples are taken for further analysis.

Drill fluid is not required, although water may be used to reduce the friction on the casing. Cutting are retrieved to the surface by means of a reverse circulation air and subsequently separated using a cyclone.

Generally, Becker Hammer drilling a geotechnical drilling method used for exploration and penetration testing in deposit which contains coarse particles, such as gravels or cobbles where standard drilling techniques and SPT testing is not suitable.

This drilling method is covered in the International Standard Practice ASTM D 5781:1995 Guide for use of dual-wall reverse-circulation drilling for geo-environmental exploration and the installation of subsurface water-quality monitoring devices

The Main Benefits of Using the Becker Hammer Drilling Are:

- Able to drill through soft to very hard material

- Possibility to obtain continuous cutting samples

- Drilling fluid is not required

- Becker blow count can be correlated to SPT blow count

- No rotation is required

- Drilling and casing the borehole is done in one single operation, therefore reducing the duplicated effort of drilling and then casing.

- Provides a continuous sampling

- Faster penetration of sand, gravel and boulder formations than conventional methods

The Main Downsides of Becker Hammer Drilling Are:

- It is not recommended to be used for strong rock

- It is a relatively expensive method

The Becker Penetration test (BPT), also known as the Becker Drill Test, characterizes soil strength based on the number of blows required to drive the last 300mm of the casing. No sample is recovered during the test. The Becker penetration test is used to check the density of granular soil sites when the ground is too coarse for the Standard Penetration test (SPT) or the Cone Penetration test (CPT).

In gravely soils, SPT or CPT resistance values may be inaccurate and too high. BPT is normally done after SPT and CPT have been attempted on the site.

There are correlations between the Becker test and other extensively used in-situ tests, such as CPT or SPT tests.

Fraser Valley Geotechnical Drilling utilizes a specifically developed version of the Becker Penetration test, contact us to learn more about the Fraser Valley Geotechnical Drilling Becker Penetration test (FBPT) method.

The Fraser Valley Geotechnical Drilling – Becker Penetration Test (FBPT) consists of attaching an oversized closed bit to the Becker casing and a mud injection system to “lubricate” the casing.

This lubrication permits driving the closed bit to deeper depths due to the decrease in rod friction. A new BPT-SPT correlation is recommended for the FBPT tests to correlate to the equivalent SPT-N value.60. The present correlation does not have a friction component. The test requires an independent site correlation of the SPT blow counts with the corresponding FBPT blow counts.

Fraser Valley Geotechnical Drilling Depends On the Right Equipment to Perform Becker Hammer Drilling.

Two sizes of Becker drill casing are commonly in use: (1) 5.5-inch OD x 3.25-inch ID and (2) 6.6-inch OD x 4.25-inch ID with two types of Becker drills, the AP-1000 and the HAV-180. Both drill types utilize the same International Construction Equipment (ICE) Model 180 diesel pile driving hammer.

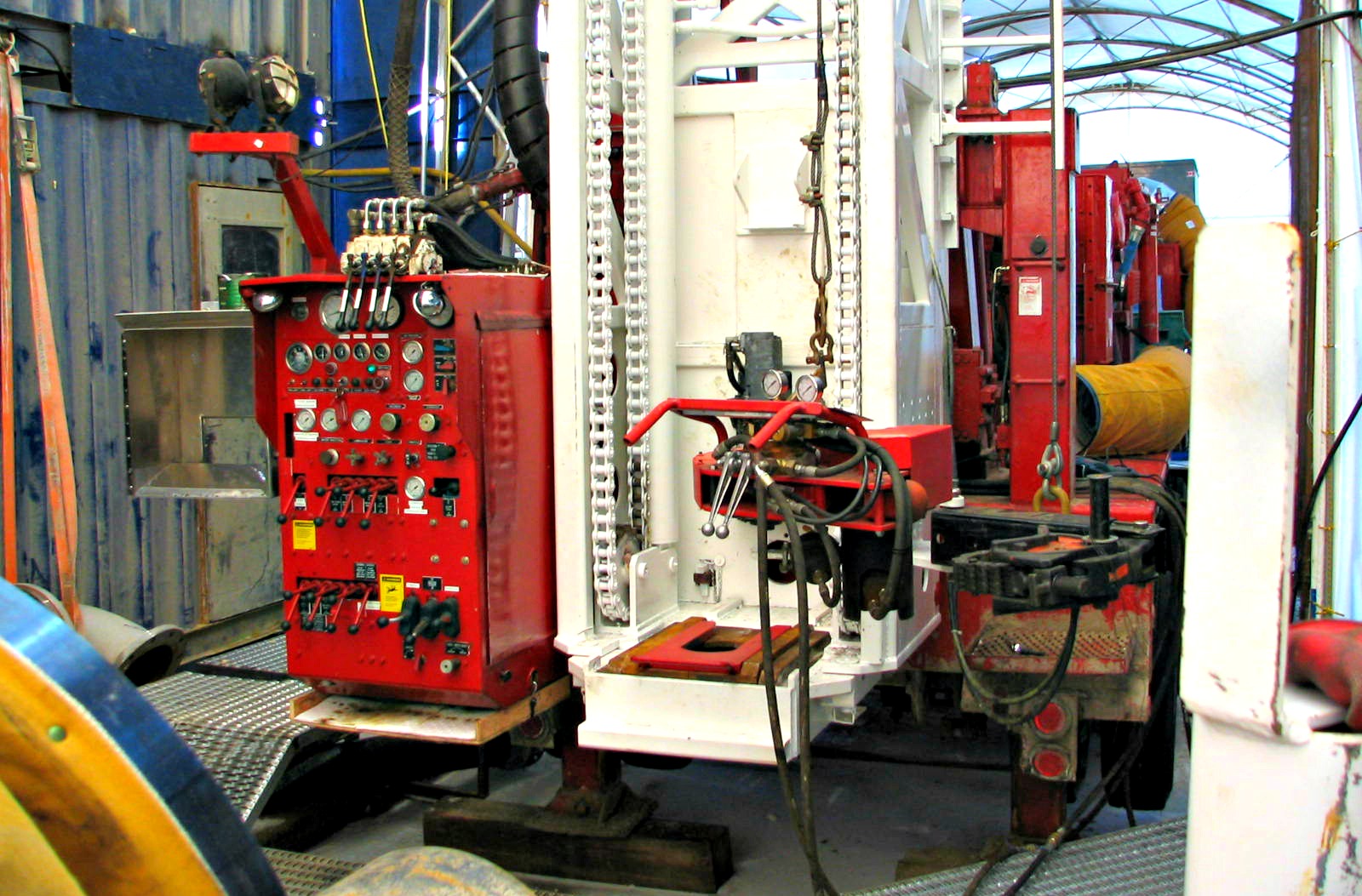

- HAV-180 Becker Hammer – The HAV-180 has a quick attachment for a top drive rotary head that allows mud rotary and coring operations to be performed below the hammer casing. This drill is equipped with Bounce Chamber pressure readouts and pull back test equipment.

- AP-1000 Becker Hammer Drill – Becker Hammer drills combine the driven energy of a diesel pile driver and reverse circulation air lift with dual wall casing. This system is well suited for most ground types but will outperform all equipment while drilling coarse granular formations. The AP-1000 has a quick attachment for a top drive rotary head that allows mud rotary and coring operations to be performed below the hammer casing. This drill is equipped with Bounce Chamber pressure readouts and pullback test equipment.

Fraser Valley Geotechnical Drilling has access to a large inventory of Becker tooling available to accommodate all your project needs.

Contact Fraser Valley Geotechnical Drilling or Tap-to-Call 778-949-4039

A: Fraser Valley Geotechnical Drilling – Overburden & Rock Coring Drilling:

Rock coring drilling is required to assess the quality of the rock before a civil or geotechnical structure is being built. The cores allow the specialists understand exactly what rocks are present as well as identify the boundaries between sandstone, limestone and shale.

A standard core is a soil rock cylinder with an approximate diameter of 4-5 inches and about 30m long. Rock cores provide indications regarding the geological and engineering nature of the subsurface material. These fundamental parameters are used in the design and construction of the geotechnical or civil infrastructure.

Rock cores are normally retrieved using wire line methods. A typical core drilling setup involves a drilling rig with rotatory power, casing, rods, hoisting system, core barrels, bits, liners and pumps with circulatory system. Auxiliary equipment must include required tools for hoisting and coupling and uncoupling the drill string and other items.

Rock core drilling is described in the International Standard Practice ASTM D2113 Standard Practice for Rock Core Drilling and Sampling of Rock for Site Exploration, which covers the guidelines, requirements, and procedures for core drilling, coring, and sampling of rock for the purposes of site exploration.

There are Three Main Types of Coring Bits:

- Diamond bits – hard and expensive bits which produce high quality coring

- Synthetic bits – Less expensive than diamond bits and in general, quality cores can be obtained.

- Tungsten carbide – this is the least expensive and the coring rates are slower

Rock core drilling, also known as diamond drilling, can be used to obtain continuous sample cores of soil and rock using a drilling fluid (if required), which can be air, water or mud. Diamond coring provides a continuous record of the lithology nor readily available from rock cuttings.

Diamond coring is a common method for extracting rock core samples, particularly suitable for semi-consolidated and hard rock. Downward pressure and high rotation are used to advance the diamond bits (drill bits faced with diamond impregnated steel) and the rock samples are normally retrieved using a wireline system.

There are 5 main wire line tube sizes generally used: AQ, BQ, NQ, HQ and PQ, having AQ the smaller core diameter (27mm) and PQ the largest (85mm). The choice of the tube is a trade-off between the required rock core diameter and the feasible drill depth.

Fraser Valley Geotechnical Drilling employs the top experts with custom designed tooling and vast experience to perform successful NQ3, HQ3 and PQ3 overburden coring. The diamond impregnated bits are custom designed, and a retractor core system is used for unconsolidated sediments. Fraser Valley Geotechnical Drilling has a wide range of drilling equipment able to perform overburden coring, such as:

- CSR 1000 – Overburden Casing Systems and Reverse Circulation Drilling PQ and HQ Coring

- HT 500 series drill – Wireline Coring BQ to PQ

- HT 750 series drill – HQ core depths to 500 feet

- HT 700 series drill – Wireline Coring BQ to PQ

- HT 1000 Top Drive Rotary Drilling Rig – HQ Core to Depths of 2,000 feet

- HT 2000 Top Drive Rotary Drilling Rig – Wireline Coring BQ to PQ

- HT 2500 Top Drive Rotary Drilling Rig – HQ Core to Depths of 3,000 feet

- RSD 100 Track Mounted Rotary Drilling Rig – Wireline Coring BQ to PQ,

- Schramm T-685WS Rotadrill – Top Drive Rotary Drilling Rig – Overburden Casing Systems

- Simco 5000 Top Drive Rotary Drilling Rig – Coring BQ to PQ and CP Coring

Fraser Valley Geotechnical Drilling utilizes a significant inventory of Overburden & Rock Coring Drilling tooling available to accommodate all your project needs.

Contact Fraser Valley Geotechnical Drilling or Tap-to-Call 778-949-4039

Local Water Well Pros

Vancouver, Whistler, Burnaby, New Westminster, Chilliwack, Abbotsford, Clearbrook, Mission, Surrey,

Langley, Coquitlam, Port Coquitlam, Maple Ridge, Pitt Meadows, Ladner, Tsawwassen

Local Water Well Pros ©